|

|

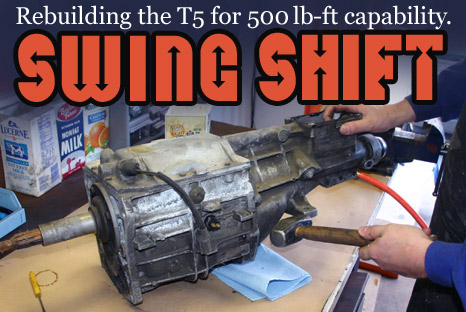

For small block Ford enthusiasts the T5 manual transmission may be

the greatest thing since sliced bread. With five fully synchronized forward gears, overdrive, an internal shift-rail mechanism

and the ability to handle over 300 lb-ft of torque, the T5 is easily the number one choice of anyone considering an auto to

manual transmission conversion. The compact dimensions and feather-like weight (75 lbs.) also makes it well suited for

competition oriented Mustangs to restomoded Falcons and Comets looking for a modernized drivetrain.

Subsequent to the

T5 the only worthwhile manual gear box to put behind a modified, yet street driven, small block Ford was the tremendously

popular Ford four speed "Top-Loader". Other manual transmissions were certainly available to put behind a 302 engine, such

as the Borg Warner T10, the English sourced Dagenham four-speed (factory option in most 60's Mustangs and Falcons). However

none of these transmissions offered overdrive, perhaps the single biggest reason that enthusiasts seek out a T5 transmission

swaps. The four-speed SROD's boxes had overdrive, but not suitable behind any significant power levels.

T5 Evolution

Borg Warner/Tremec World Class T5 |

Ford began using the Borg-Warner designed T5 in small passenger

cars in the early 80's. However these early non-World class (NWC) models weren't suited to handle the power of modified V8

engines, and it wasn't until the availability of the World-Class (WC) T5 gearboxes designed for the new fuel injected 5.0L

Mustangs that the popularity of the transmission took off. Compared to NWC T5's the WC's benefit from needle bearings under

the gears and tapered roller countershaft bearings for reduced friction. This change also allows the later to run considerable

less viscous ATF fluid rather than heavy gear oil. The blocking rings are upgraded from brass to fiber lined steel for smoother

gear synchronization. The early WC T5 versions were rated to handle 265 lb-ft of torque, while subsequent changes to gear

material and size in 1990 bumped the torque rating to 300 lb-ft. The 1993 Cobra T5 was rated to handle 310 lb-ft, while Ford

Racing's aftermarket "T5-Z" could handle 335 lb-ft as a result of a smaller first gear (2.95:1 compared to 3.35:1) and stronger

steel.

Making the T5 Stronger

While

it may seem a 300 lb-ft rating is easily surpassed with today's cylinder heads and camshafts, in reality most T5's can easily

endure well over that figure when used in street driven applications. In fact our experience has been that shifting style,

and not torque rating alone, is the biggest factor is the life of a T5. We've seen power shifted T5's snap behind stock 5.0L

engines, while on the other T5 hold up mile after mile behind stroked Windsor's. In fact, our own Project '67 has been running a stock 1990 T5 for nearly five years. We've made

over several hundred 11 and 12 second passes launching at 5000 rpm on slicks. Admittedly we are biding our time with this

T5, and with the recent addition of a supercharger, we're not pressing our luck any longer.

It

used to be that once you got in to the 500 horsepower range you were well beyond the capabilities of any T5, and it was time

to think Tremec TKO (incidentally, TTC, the company which owns the Tremec brand, bought the T5 design and tooling from Borg

Warner in 1997.) However no longer is this the only option. G-Force Transmissions, the maker of some pretty stout competition

gear boxes, also manufacturers high strength gears, shafts and other internals for the T5 transmissions. When properly assembled

the G-Force T5 can handle 500 lb-ft of torque. While there are still strength limitations of the stock T5 case (G-Force does

offer their own T5 case) the stronger internals are the key to keeping a T5 together behind a stout small block. G-Force offers

their T5 gear sets in synchronized and dog-ring versions. Dog-ring refers to the modification of blocking rings

for synchro-less engagement. This make shifting easy at high rpms but at the expense of tougher gear engagement at lower rpms.

We selected the fully synchronized kit for good streetability.

While the G-Force components are built to be bullet

proof, that is only half of the recipe for an indestructible T5. The other half is in the proper rebuilding of the T5. In

fact, most of the nations major T5 rebuild shops offer their own "G-Force T5" versions, which include their own personal,

and often closely guarded, secrets for success.

The G-Force synchronized replacement gearset.

The kit includes new cluster shaft (top), 26-spline input shaft, and 1st, 2nd, and 3rd mainshaft gears. Also come with a

G-Force output shaft (not pictured.)

The G-Force gearsets are made from 9310 High

Nickel Steel, and are 1/8" thicker than the stock gears (left).

Another highly recommended T5 upgrade is the

G-Force heavy-duty rear bearing retainer (right). The stock unit (left) tends to flex under high loads which can result in

excess countershaft play.

|

|

|